Alisa Ota Tietboehl reflects on her journey growing up around the world, where she developed a passion for Japanese craftsmanship and textiles.

(A message to the reader.)

MAOTA is an apparel brand from Japan founded by my husband Masaaki Ota and me, Alisa Ota Tietboehl. I was born in Bonn, Germany to a Japanese mother and German father. My career has led me to experience different perspectives on the design industry. I have experience in trend and colour research, creation and elaboration of technical drawings, creating and designing ranges. Graphical visualisation in the area of print, development of a graphic strategy for clients and typography skills are my expertise as a graphic and communication designer.

Being born into two cultures and raised by multiple, I was able to see the world through completely different eyes. My world was filled with colours, textures and senses throughout my life. While growing up in rich, traditional cultures, I was fortunate to have been exposed to art and design from a young age due to my parents’ passion for pottery, textiles, foods and art. My Japanese grandmother introduced me to the art of kimono, and that is when I became fascinated with its beautiful craft.

Germany, on the other hand, is more product design and typography focused. Some of my favourite fonts are made by typographers from Germany and the design is more practical. Combining these two forces I have found a balance in my career, where I can implement both worlds and merge them into my passion. My own multi-cultural background and interests in other cultures, together with a knowledge of several languages, have left me passionate about textiles, craftsmanship and traditions in art and culture.

My husband Masaaki Ota was born in Hamamatsu, Shizuoka in Japan and was passionate about fashion from Europe from his teenage years. After graduating from “Bunka Fashion College”, where he was able to perfect his pattern-making skills and learn the technical art of apparel creation he moved to London, England to study at the “London College of Fashion”. After returning to Japan, he joined “Yohji Yamamoto” and worked as a pattern maker. His passion for apparel led him to study more about textiles and how they are created, so he joined a fabric manufacturer in Ichinomiya, Aichi Prefecture. Eight years later, he started working for a sports apparel company from Germany, gaining experience at the brand’s Japanese and US subsidiaries. After about three years he went back to Japan and founded MAOTA in 2020.

Both of us met in Tokyo at the sports apparel company and got married and moved to Portland, Oregon for my husband’s work. After being in the industry for over 20 years and having seen many challenges and opportunities, our passion has always been about Japanese craftsmanship and combining our different strengths. We care deeply about creation and sustainability. Not only from an ecological point of view, but also sustaining the Japanese craft that has been around for centuries.

Masa, my husband, is in charge of pattern making, textile creation and being in close communication with the different factories we work with. I am in charge of web design, social media, communicating with media outlets and everything related to graphic design. Combining our strengths we found a good balance between our passions and learning about each other’s strengths.

“The idea is not to show off your skill, use it instead in places people don’t see, And always keep finding ways to make improvements. Never stop tweaking- that’s the bedrock of craftsmanship.”

quote by a Japanese craftsman

With continuous support from local craftsmen (and women), we are committed to a maintained visible production. We are based a short distance from our weaving mills, yarn factories, dyeing mills and production factories in Japan, making possible frequent visits and keeping the production local. We use high-quality yarns which are the base for unique textures, shapes and colours.

We strongly believe in slowing down and a wardrobe that transcends seasons. With an emphasis on craftsmanship, our aim is to design high-quality products with longevity in mind, selecting materials and techniques crafted causing as little damage as possible along the way.

Yarn is the beginning.

Colours live deeply in life and culture as many paintings, textiles, ceramics, poetry and literature. A quiet atmosphere that seeks harmony with the light, and the world of wabi-sabi and loneliness. The colours of Japan that have been added in the course of history are beautiful and elegant.

We focus on traceability and have been following this yarn’s journey from the very beginning. From choosing the yarn, dye colours to the weaving strength and working face to face with craftsmen (and women) to create this special blend of wool and cotton.

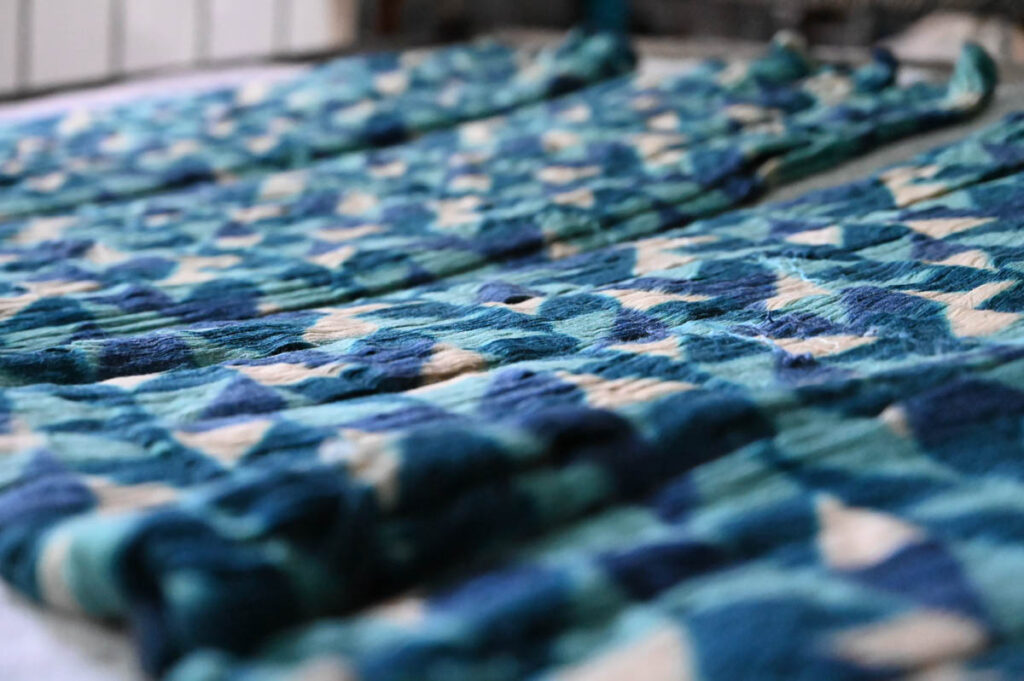

This fabric looks Denim but technically it is not Denim. There is a surprising texture and feel as well as lightness to the fabric. Five different yarn-dyed colours make the fabric colour so rich and special. The subtle greenish blue colour is inspired by the genuine indigo colour (called aizome in Japanese) which you can only see in the process of dyeing, before oxidation.

1) Yarn Dye

The yarn is put into water to be wet, so that the yarn can absorb the dye easily. The yarn is then dyed as a modern version of kasuri dye. Kasuri dye is a way to dye yarn in multiple colours to achieve a special surface on the fabric. The dyeing mill is using a customised machine to make the kasuri dye. After the yarn is dyed, the yarn is put into a steaming machine to set the colour. Without steaming, the colour will gradually fade.

2) Yarn Reeling

When the yarn is fully dried, it goes into a hank reeling mill to be made into yarn cones to prepare for the weaving process. This process is made by an 84-year-old humble craftswoman, who invited us for coffee first before explaining to us each step of the reeling process. Her words have stuck with us since then “You gotta learn the tricks yourself. Respect for her craft and a willingness to keep learning is the heritage of Japan.

3) Weaving Mill

- Weaving mill

- Weaving mill

- Weaving mill

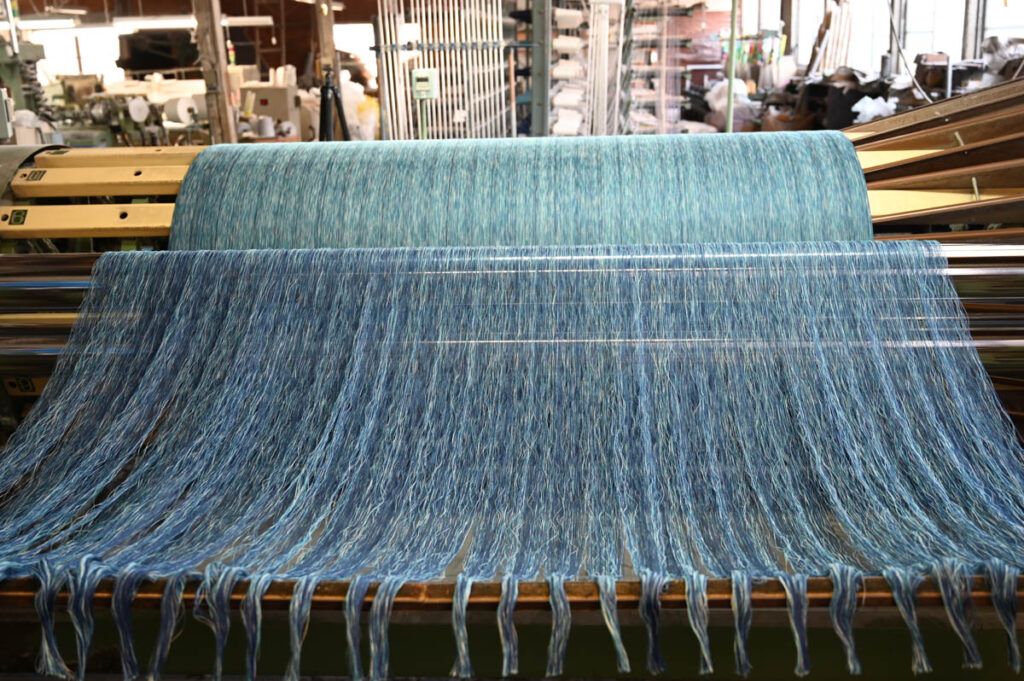

Once the yarn cones are ready, they go to a weaving mill. Since each yarn cones are big, they need to be divided into smaller yarn cones for warping. Warp is the grain line (lengthwise yarns) of the fabric. Warping is the process of combining yarns from different cones together to form a sheet. The important point in the warping is to preserve the yarn elongation and maintain it.

After the warping process, the weaving can start. Weaving is the process of combining warp and weft components to make a woven structure. Once the weaving process is done, the fabric is sent to a finishing mill. The fabric before the finishing process is called greige. In textile manufacturing, finishing refers to the process that converts the woven fabric into a material to improve the look, performance and hand feel of the finished fabric.

4) The finished fabric is then manufactured into garments.

- Julia

- Rogerio

In MAOTA’s collection, it is a jacket and pants.

Being able to watch each process and follow each fabric’s journey is a privilege we have, because we care about our craftsmen (and women). We frequently communicate with them, we are willing to learn and make adjustments. We value each process and each person that is involved in making our garments. Each field respects each other’s strengths and working together as a team has been one of the many learning experiences, which I am grateful for.

Quality, timelessness, long-lasting, craftsmanship and comfort in the movement are MAOTA’s main passions to keep Japanese craftsmanship and traditions alive. Heritage inspires the future.

A detailed video of the process can be seen here.

Currently, we are working on our second collection, which will be launched this autumn.

Visit www.maotajp.com

About Alisa Ota Tietboehl

I was born in Bonn, Germany to a Japanese mother and German father. I grew up in Bangladesh, Spain, Japan and Germany. Currently, I live in Tokyo, Japan. My own multi-cultural background and interests in other cultures, together with a knowledge of several languages, have left me passionate about textiles, craftsmanship and traditions in art and culture. I am a graphic and communication designer currently navigating different projects in apparel, textile, trend research and as a guest writer for www.trendland.com. Currently, I work together with my husband on our brands MAOTA and naensis, which are both an ode to Japanese craftsmanship, sustainability and a passion to keep traditions alive. Visit www.alisa-alisa.com (personal website) and www.naensis.com (coming soon)

I was born in Bonn, Germany to a Japanese mother and German father. I grew up in Bangladesh, Spain, Japan and Germany. Currently, I live in Tokyo, Japan. My own multi-cultural background and interests in other cultures, together with a knowledge of several languages, have left me passionate about textiles, craftsmanship and traditions in art and culture. I am a graphic and communication designer currently navigating different projects in apparel, textile, trend research and as a guest writer for www.trendland.com. Currently, I work together with my husband on our brands MAOTA and naensis, which are both an ode to Japanese craftsmanship, sustainability and a passion to keep traditions alive. Visit www.alisa-alisa.com (personal website) and www.naensis.com (coming soon)

Comments

I have a modern concept to dye the yarn in all conditions of temperature and pressure with good quality of dyestuffs.