Some of my earliest memories are of watching a carpenter build a room extension on our house where I grew up on our farm at Mole Creek, Tasmania. I was probably around 4 or 5. I was absolutely fascinated.

As with most farmers, my dad was a jack of all trades and especially good at carpentry. I loved watching him make anything from wood, from farm gates to out-buildings.

So I guess I learnt a lot through “osmosis”, plus the tips I would get from dad.

Woodturning was completely self-taught. I bought my “Tough” lathe in 1977 which I still use to this day.

We launched Indeco in 1992 after having completed a NEIS (new enterprise incentive scheme) course. NEIS provided financial support for the first year and we experimented with a few different lines and then opted for kitchenware: everyone has to eat. We needed a “bread & butter” item for cash flow and came up with the spurtle. I’m not sure whether it was a suggestion or came upon it in our reading. And I was a big fan of porridge so it fitted the bill.

Our design philosophy is minimalist with little decoration or embellishment, striving for beauty through line and proportion; “less is more”. Plus the fact that there are no quirks or beads to trap food residue.

The spurtle is not just a straight tapered cylinder, it is slightly waisted in the middle thus giving it a better aesthetic, we feel. Turning the spurtle is quite a straightforward operation, taking care to support the slender work with one hand whilst making the final cut.

In the past, we thought Celery Top Pine made the best spurtle, but salvaged timbers such as sycamore (Acer pseudoplatanus—it’s regarded as a weed in some Tasmanian jurisdictions) are also ideal.

A spurtle is used instead of a spoon because it is less likely to form lumps. The spurtle allows the oats to be stirred without the dragging, as happens with the head of a wooden spoon. Not only does this prevent lumps, the spurtle’s smaller surface area also helps prevent the porridge from sticking to it.

To turn a spurtle it takes about 3.5 minutes. That excludes selecting the timber, sawing to size and finally branding. On a good day (eight hours), I’ve managed to make between 50 and 60, that is the whole operation from go to woe.

Photos of the spurtle-making are by Patrick and Mieke Senior.

- A spurtle that Sharon Peoples bought 12 years previously from Design Tasmania

- A spurtle used by Kate Torney

Author

I was born in 1952 and grew up on a farm in Mole Creek, Tasmania. Worked in an office for about eleven years and then met Mieke. We then travelled to her home country Belgium and lived there for about 15 months. We then returned to Oz. I did an Applied Design (wood) course at the TSIT in the early 80’s and this enabled me to seek work with a furniture maker, where I worked for four and a half years. This gave me skills in production furniture, jig making and wood machining. We then did a NEIS (new enterprise incentive scheme) course in 1992. Financial support equivalent to the Dole and a business plan. And then launched INDECO (INnovative DEsign COmpany) in June 1992, making wooden kitchenware. And we’ve been adding to the range since.

I was born in 1952 and grew up on a farm in Mole Creek, Tasmania. Worked in an office for about eleven years and then met Mieke. We then travelled to her home country Belgium and lived there for about 15 months. We then returned to Oz. I did an Applied Design (wood) course at the TSIT in the early 80’s and this enabled me to seek work with a furniture maker, where I worked for four and a half years. This gave me skills in production furniture, jig making and wood machining. We then did a NEIS (new enterprise incentive scheme) course in 1992. Financial support equivalent to the Dole and a business plan. And then launched INDECO (INnovative DEsign COmpany) in June 1992, making wooden kitchenware. And we’ve been adding to the range since.

Comments

Well, I inherited my mother’s spurtle that formerly belonged to her mother (Both of Welsh extraction and native speakers) and while a spoken/written description might mean it sounds like the one imaged I can say mine is not at all like that. It is indeed wood (not sure which was used in this case – it’s old and been in too many porridge pots) and does have a tapered bottom end (that moves across the base of the pot) and is smoothly easy to clean and un-embellished by decoration. But, it’s not cylindrical but a blade that is flat one side and gently curved on the other. The blade part is gracefully waisted in the middle but there is a distinctly smaller diameter handle section from a little over half-way up the length that tapers up to a wider end which fits the hand perfectly. So its more like an elegant feather than anything cylindrical but with every surface and corner softly rounded – which may be due to its almost century of use but my feeling is that it was probably originally made that way.

Thanks for this Raewyn. It is a great testament to the value of such a simple handmade object in our world. Do you have an image of your spurtle you could share?

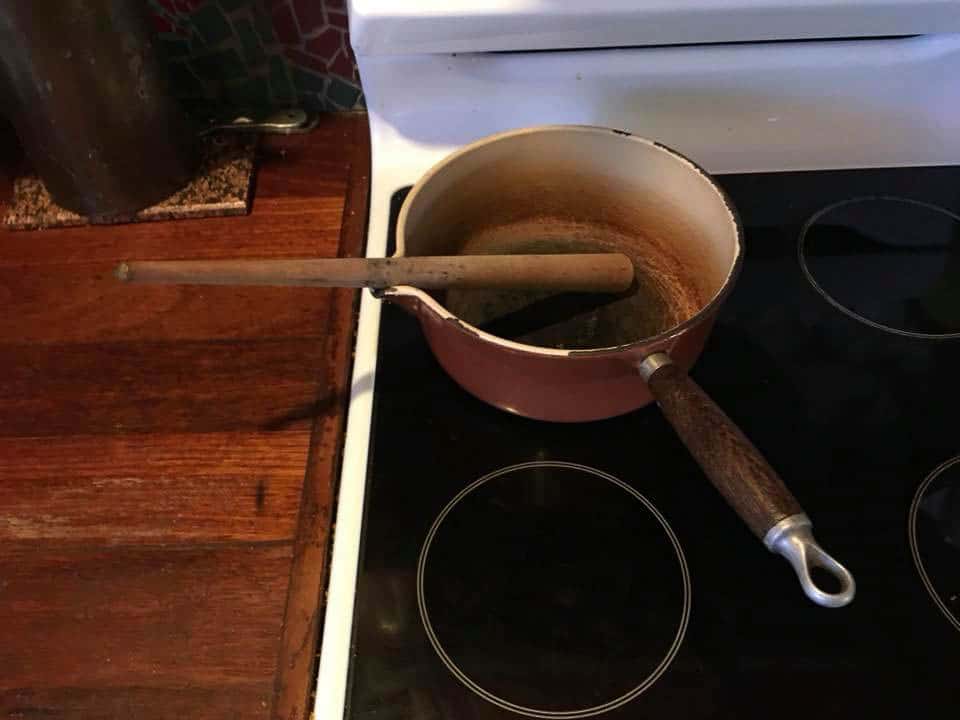

Kevin that was me (Moyra) not Raewyn. We share a blog site hence the confusion. Sorry but right now I cannot get an image. Haru took it for repair because of my distress that someone burned it a bit by leaving it in the pot on the gas stove and it was badly marked. It went into his office somewhere and now he cannot find it. I’ll send one once he does find it.