- Milward Mug with extruded handle

- Milward holding Conran Portmeirion teapot

- Milward holding Conran Portmeirion prototype

- Milwards workshop 3D-printed cup and his laster prototypes

- Left Conran Portmeirion slipcast, right Milward wheelthrown mug

- Stacked Plates emphasizing planned Irregularity

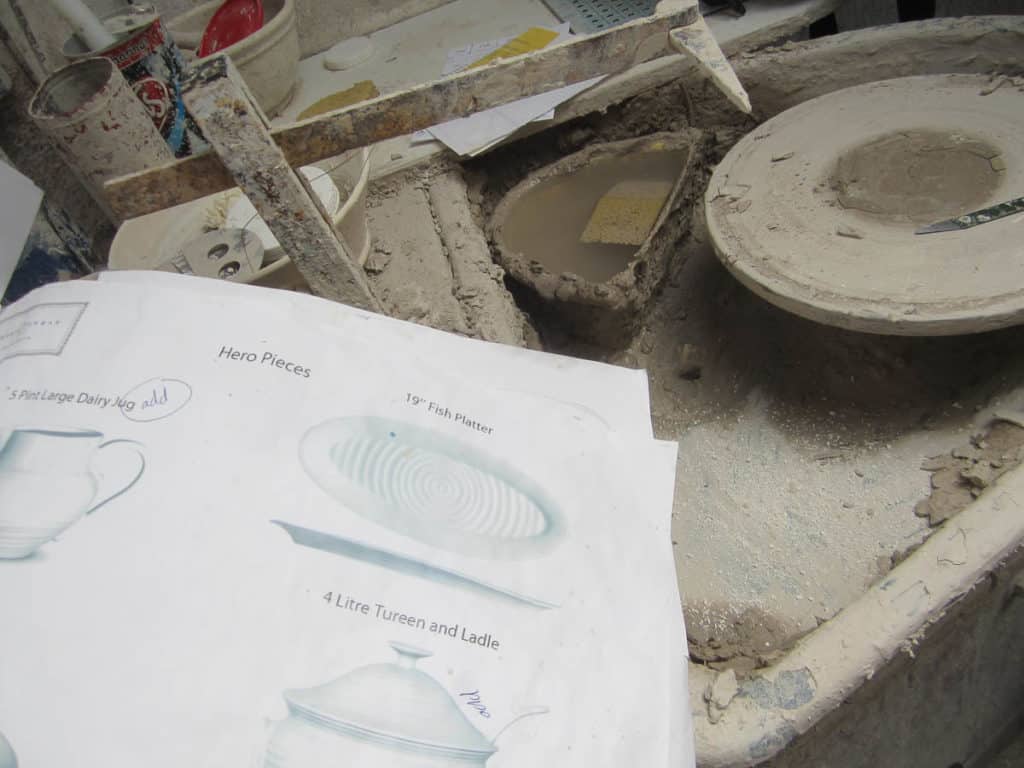

- Portmeirion blueprints in Milward workshop with his wheel

- Sophie Conran for Portmeirion in Stoke on Trent outlet shop

- Sophie Conran for Portmeirion in Stoke on Trent outlet shop

To lift a cup that one has not touched before is often like shaking the hand of a new acquaintance: quickly, one gauges a sense of compatibility and the possibilities and limits of pleasurable engagement.

(A message to the reader.)

To discover craft that is responsive to one’s own human wants, needs and pressures, imaginary and invented, is to feel fully alive—and so there is good reason not to praise dead heroines and heroes of existing and established genres, materials and canonical types. Reacting to the contemporary moment is essential to keeping craft a process of invention and what it does so powerfully—act as a mode of self-invention, often for both maker and user. A consideration of a craftsperson who has worked in industry anonymously for decades highlights the fact that skill still matters. Their limited autonomy and individuation is worth weighing in relation to our prevailing belief in craft’s tendency towards obsolescence.

Kevin Millward drifted into the Gladstone Museum in Stoke-on-Trent for a brief spell as a demonstrator and left because of his restlessness and desire to be self-employed. He juggles contract work for firms and selling his own ware with occasional teaching. Millward’s hands are remarkable because of his skill but also the breadth of his output—small-scale artisanal production and large industry rely on him. Millward is fascinating because his obsolete skill has never been more applied to tangible goods and yet never garnered less respect. His prototypes for mugs and plates are reproduced in the hundreds of thousands. When I first met him in 2013, he was keen to walk through the Portmeirion outlet shop in Stoke-on-Trent and identify each piece he had made—or is it designed? Or is the right term “potted”? To dispel my disbelief, he showed me his iPhone, which was loaded with images of unfired greenware in his studio that matched the Sophie Conran line on display—the same rippling wobble was in all the pottery. The reason for my shock was not that I had imagined that Portmeirion’s work was actually made by Sophie Conran, daughter of Sir Terence of Habitat and Conran Shop fame. I had not envisioned her at the wheel, centring 5 pounds of clay as the muck splattered about. A jaded consumer, I had guessed incorrectly that behind the Conran branding effort was a committee of marketing specialists and focus groups that imagineered these well-branded commodities by sending a digital file overseas to outsource production—and that the potter’s marks were probably simulated. A historian, I mistook the potter’s wheel to be obsolete. But twenty-first-century technology has not displaced the wheel or the individual potter as a resource. Millward lives in a bucolic hamlet outside Leek, near Stoke, and his wheel-thrown pots are sent to China to be copied— slip cast in moulds with all of his texture and his imperfections intact—and then shipped back to be advertised online by Bed Bath & Beyond as tableware “with a nod to Japanese serenity and a wink to English eccentricity”.

Kevin’s workshop confounds because his artisanal skills are visibly resolving a myriad different artistic identities, giving shape to both corporate lines of ware and small batches for studio potters who advertise their work as being made with “a personal touch”. Whose expression and self-expression we see is difficult to sort out. Apart from the wobbly ware marketed under the Sophie Conran label, Kevin supplies sleek teapots to Portmeirion if it needs a more refined shape. Other jobs include making trays for a robotic system to feed people with quadriplegia, bespoke mortar and pestle sets for gourmets, rustic French jardinières and, perhaps most strikingly, mugs that are retailed at the Covent Garden market and elsewhere as another artisan’s limited-edition wares. Whether the mugs are imbued with an individual’s personality or a committee’s is also complicated to disentangle. If uniqueness is being subcontracted out to Kevin and he works as an alternate craftsman, he doesn’t mind remaining anonymous so long as the customer pays. As he sees it, his success lies in his manual handicraft, eye trained in figure-drawing classes and, most of all, his ability to “put any genre on”. His sublimation of his own ego might not seem to be a skill to many, but it is—and once was a traditional part of being a craftsman.

Inhabiting other aesthetic sensibilities and being efficient at the potter’s wheel are virtues Kevin realizes were once commonplace in Stoke but are now rare. Such assets have been dropped from the art school curriculum as well the factory. He taught at universities but has found that students perceive him as a contractor, and that they were not interested in an apprenticeship or in learning techniques so much as realizing design schemes by relying on him. His virtuosity at potting is such that when one of the most outspoken champions of handicraft, Emmanuel Cooper, was asked to pose in an advertisement for a wheel, he asked Kevin to throw an enormous bowl on the wheel—Cooper’s own skill not lending sufficient hyperbole to the advertisement. Millward showed me several styles and lines that he copied for studio potters to fulfil their orders. He throws fifty mugs in one hour—speed and consistency that make his hands highly sought after. Kevin understands that he cannot necessarily throw precisely like another potter because their physiques might differ, but he knows he is more proficient at being his clients than they are.

Kevin proves the potter is economically viable in our age of digital artistry that loudly applauds the gadgetry of 3d additive printing or cnc subtractive processes. Corporate designers generate three-dimensional designs in a computer program such as Rhino, taking a day and nearly a thousand dollars to print out one pattern. He shows me a finished prototype, a yellowish thermoplastic object, which could not be moulded because the corners had too sharp a radius; he made adjustments to the form by quickly casting it in plaster. In the development of a new line of merchandise, a marketing department might reject the proportions of a shape or want various slight adjustments to be attempted and tested, so to employ Kevin Millward to make a hundred prototypes on his potter’s wheel is still more efficient and economical than to use the latest digital technologies.

Millward still makes his own work, too, and looking at it one can see why Portmeirion’s director of design selected him to realize Sophie Conran’s tableware. He declares his own work “wibbly-wobbly pots”. The pottery does have more emphatic hand marks, like a bowl with indentations knocked in when the clay is still wet. Compare his own mugs to the ones he threw for Portmeirion to reproduce: both have a conical body. Millward’s own is squat with a wider foot. Portmeirion’s Sophie is more photogenic but tapers so much that it’s tippy. In Millward’s view, the Sophie mug “looks right but functions poorly”. It works best when solely viewed on the Web. The handles differ more, as his is an extrusion—an eighteenth-century method of producing standardized tubes of clay—that he imprecisely joins, tearing the tube open visibly on the thumb rest. On Portmeirion’s Sophie, the pulled strap handle resembles a puffy ponytail on an adolescent cheerleader. Portmeirion pottery is purchased online often, so looks rate higher than touch as a priority in marketing. Millward is supplying Portmeirion with what it wants—what he calls “a diluted version of bad 1960s pottery”—and the skilled potter knows he is dumbing down his handicraft. He made several variations and disagrees with Portmeirion’s choice but also understands that the decision wasn’t his to make. But he recognizes his choice probably would have proven less successful in the marketplace. His own design for an extruded handle is a sophisticated tactile subtlety, a detail that is probably lost on many users and is impossible to mass produce by casting in moulds.

The Sophie teapots are crowned with wiggly lids, an idiosyncrasy to give the consumer a visual sense of tactile engagement and the pot a strong personality—but whose? Millward remembers his instructions from Portmeirion: “add a bit more wobble to the knob”. The plates stack and fit our industrial lifestyle of dishwashers but have eccentric lips that droop. It is noteworthy that when the line debuted in 2006, the work stream was outside the factory’s comfort zone. At the garden party to announce the new line of manufacturing, marketing was ahead of production. When the press caught its first glimpse of Portmeirion’s Sophie Conran line, they ate off a dozen matching sets of luncheon services that Millward himself had thrown on the wheel. Yet no one wrote it up as handicraft; it was deemed a new industrial design. Millward’s proficiency is such that his pottery is consistent enough to appear to be factory-produced. When the tableware was met with intense interest and an award, Portmeirion expedited the shipment of Millward’s prototypes overseas to have the pottery copied and produced en masse in China. Proud of his work on the Sophie models and of his ability to “put his business hat on”, Millward is resolved that “No one would buy it if it had my name on it,” adding that the product carries in it four crucial components: his craftsmanship and sense of form, the art director of Portmeirion’s savvy marketing, Sophie Conran’s own sense of form and style; moreover, perhaps most important of all, the Conran name, an English regal provenance that is the contemporary version of eighteenth-century aristocratic approval, such as Wedgwood’s association with the Duchess of Devonshire or Sèvres with Madame de Pompadour. Virtuosic potters once aimed for standardization and visual coherence.

Does Millward’s pottery for Portmeirion confirm David Pye’s warning that “the danger is not that the workmanship of risk will die out altogether but rather that, from want of theory, and thence of standards, its possibilities will be neglected and inferior forms of it will be taken for granted and accepted”? These attempts to cultivate sentimental associations in household goods are age-old strategies, and Pye’s fears are warranted, but shoddy workmanship is nothing new: it is not standards that we should invest in but genuine education in handicraft.

A man with a sense of humour and scale in the world, Millward is irreverent towards studio potters who speak of the “handmade” with moral superiority and the self-assurance that such a thing exists. His potter’s mark can be contrasted with that of the English potter Edmund de Waal, whose austere cylinders thrown on the wheel are exhibited in massive shelving units— recently to critical acclaim at the Gagosian Gallery, New York City. If de Waal’s initials are impressed into the wet clay on their sides—visibly artsy signatures—Millward’s blue rubber stamp, “Handmade in England”, is out of sight, on the base of his own mugs. Millward thus emulates mass marketing even as he asserts the role of the human potter. His name is mentioned nowhere in Portmeirion’s publicity—hence my initial doubts of his authorship. Yet his labour is somehow his own, while his identity is malleable and susceptible to role-playing and reinvention.

In a so-called post-industrial economy, highly educated and skilled manual workers remain active, denying the obsolescence of craft as they submit their virtuosity to corporate goals. They are pleased to re-enter the factory reclassified as consultants—once they were mere “mechanics”. Yet the academy has systematically dismantled the programmes on which they studied. And factories no longer train apprentices in Stoke-on-Trent. Rita Floyd and Kevin Millward embody an enormous population of non-replenishable resources that we have normally never considered “craftsmen”. Skills assembled over several lifetimes of incremental and collated labour are easily lost in a generation.

The role of craftsmanship in our society is fragile and there is danger in preserving it artificially as well as underestimating the vitality of ancient skills. Millward is a rare occurrence, an anonymous craftsman identified through oral history. The great majority of craftspeople making baskets, chairs, glass, jewellery and pottery will remain anonymous. The ultimate challenge to you, the reader, is to search out and applaud the anonymous handicraft that is in your own local context, under the hood of a well-oiled machine or inside the tent at your local carnival.

Virtuosic anonymous craft has always existed in greater volume than authored and signed self-expressive craft. Anonymous craftspeople in manufacturing will outnumber craftspeople operating individual workshops—and probably always will. And women have historically outnumbered men in factory employment. One can state with certainty that there are more skilled hands in factories making pianos today than there are individual studio craftsmen able to bequeath such skilled instrument manufacturing to the next generation: the piano has always needed several skills and materials joined together.

So how should we cultivate future craftspeople and craft consciousness? It is high time to expand the honorific to be less of a distinction given on the basis of class or status. For other so-called ‘factory craftspeople’ I speak with in the course of The Shape of Craft (Paul Roehrig at Kohler in Wisconsin, Chris Maldari of Maldari Brothers in Brooklyn, or Rita Floyd, also in Stoke-on-Trent) it is merely their work; they don’t grandstand and call themselves artisans. Schools, museums and aesthetic movements have inadvertently ossified craft, making it a static thing. Historically, craft has developed in response to demand, inventing itself anew wherever and whenever there was patronage. Feeding cash to summer camps and cultural institutions might appear to be a way to support handicraft, but in those workshops there is as much routine production as in any tedious factory. Invention in craft and responsiveness to social need cannot be taught; it must be found. Responsibility to social needs can be taught—and should be more often. A more empirical, directly sensuous and sensible recognition of craftsmanship as it exists today is vital, urgent and still worthwhile.

We have now worked through archetypes that are pinned onto refrigerators and above desks as exemplars, and also through the messy present context, to demonstrate that there is no overriding continuum in craft history; a linear genealogical history sounds good but when set in motion often produces blinders or canonizes individuals. The practices of these archetypes should not be emulated but their responsive attempts at tooling are worth considering in terms of temporal sensitivity. A craft is always in flux.

Author

Ezra Shales teaches the history of design and craft at the Massachusetts College of Art and Design and has a PhD from the Bard Graduate Center and an M.F.A. from Hunter College. He is currently writing introductions for new editions of David Pye’s seminal books The Nature of Design (1964) and The Nature and Art of Workmanship (1968), working on an exhibition of work by Ed Rossbach and Katherine Westphal, and going in circles trying to write a book on 21st-century basketry.

Ezra Shales teaches the history of design and craft at the Massachusetts College of Art and Design and has a PhD from the Bard Graduate Center and an M.F.A. from Hunter College. He is currently writing introductions for new editions of David Pye’s seminal books The Nature of Design (1964) and The Nature and Art of Workmanship (1968), working on an exhibition of work by Ed Rossbach and Katherine Westphal, and going in circles trying to write a book on 21st-century basketry.

Comments

I so enjoyed this essay. We in studio ceramics often don’t give enough credit to the industrial producer. Very often, they have skills we can only dream about.

Nice article on Kevin 🙂